Field Clearing Sources

Stone Removal and Disposal Source Materials

Compiled by James Gage (November 21, 2024)

Note

Many of these transcriptions are derived from text recognition software used on scans of the original materials. Although modern text recognition software is quite good, errors due occur due to broken typeface, smudges, and other issues. The transcriptions have been proof read to look for obvious errors and mistakes. There still may be minor transcription errors. Please consult the original source.

PUBLISHED FIELD CLEARING ARTICLE

“Field Clearing: Stone Removal and Disposal Practices in Agriculture & Farming” By James E. Gage with a “Case Study of Stone Removal Activities in Joshua Hempstead’s Diary” By Mary E. Gage published in Bulletin of the Archaeological Society of Connecticut 76:33-81 (2014). [View PDF of Article] Also see the revised and expanded 2020 version at Academia.edu https://www.academia.edu/43358356

See the new book (2024)

Rock Piles and Field Clearing Practices on Historic Farms and Pastures in Northeastern United States: A Historical and Scientific Investigation. Amesbury, MA: Powwow River Books. Available from publisher Powwow River Books.

Ives Field Clearing Model

In 2015, Timothy Ives, Rhode Island State Archaeologist, published his “Cairnfields Formation Model” that postulated that farmers built cairns in pastures. Currently, there is no historical evidence that farmers cleared stones from permanent pastures. The model seemed suspect.

Ives Theory: Sheep overgraze pasture

Erosion takes place

Stones are exposed

Cairns are built to open up more pasture

Sounds logical!

Logical flaws in Ives Theory:

Farmer allowed sheep to overgraze pasture and expose bare ground

Farmer allowed massive erosion of soil

Eroding away 6” up 12” of soil

Exposes copious quantities of stone

Farmer picked up stones and places them in piles

Creates more bare ground

Farmer re-seeded pasture with grass

Pasture stood empty for two years to allow grass to take root

Repeat Process

Sheep allowed to overgraze pasture

Massive erosion of soil

Expose copious quantities of stone

Erode another 6” to 12” of soil

More cairns are built

Expose more bare ground

Pasture re-seeded

Pasture remains empty for two years

Repeat Process

In Reality:

Pastures were sometimes overgrazed by both sheep and dairy cows

Erosion never took place

For more information please read: Challenging Ives “Cairnfield Formation Model”

James Gage, “An Analysis of Historic Photographs of Rocky New England Pastures” (2023) Read on Academia.edu

Mary Gage, “Cairns in New England Pastures” (2023) Read on Academia.edu

Table of Contents

Source Materials

FC100

Commissioner of Agriculture

1868 Report of the Commissioner of Agriculture for the Year 1867. Washington: Government Printing Office.

“[p.6] Among the important performances of this powerful machinery [steam driven tractor] for steam culture is that of breaking up or crushing the softer rock or stones in the cultivated lands to the depth of 12 to 15 inches and incorporating them with the soil, It is a great injury to a close, stiff soil to remove all the stones from it. Besides the loss to the soil from the gradual disintegration of the stones or rocks through the action of frost or other agencies, their mechanical influence upon the soil – especially when reduced to small size and mixed with it to the depth of 12 to 15 inches – in keeping it open, facilitating drainage, and increasing its power of absorbing air, moisture, and the gases which afford nutrition for vegetation, is, to a high degree, favorable. Many years ago an able article was published in a English periodical, stating that a turnpike road, paved with stones gathered from contiguous grounds, was made through a fertile district of the country, and in a few years the lands from which the stones had been removed on each side of the road became greatly deteriorated, while those lands subject to the same system of tillage, at a greater distance from the road, and on which the stones were permitted to remain, maintained their fertility. No stones should be removed from the soil, especially a tight one, except such as are decidedly in the way of cultivation and cannot be conveniently broken up and their parts incorporated with the soil. In preparing land for mowing, [p.7] all small sized stones should be sunk into the soil, rather than picked up. Such preparation of the entire cultivated soil must be a work of time, but the point now aimed at is to direct intelligent attention to the subject as one of no small importance to the agricultural interest.” Pp. 6-7

FC101

Holbrook, F.

1848 “Removing Stones and Bushes” The Cultivator v.5 no.4 (April, 1848) pp. 105-107.

“[Lexington,MA] [P.105] When Mr. Phinney commenced, some twenty-five years ago [1823], his farm presented a most forbidding aspect. The soil was covered up with stones and bushes, shrub oaks and pines, so as to be literally inaccessible for cultivation; the fences were in a miserable condition, and what land had been cultivated, was worn out in vegetable substance under the “skinning” system. He debated with himself, for some time, whether an investment might not be made here, in the removal of these obstructions and the improvement of the soil, that would be judicious, and in the end profitable; and although men of less agricultural skills and enterprise, would have shrunk from the undertaking, he commenced and persevered. It must now be apparent to any practiced eye, that on this farm are the elements of liberal and sure reward for all former toil and expense, let the world go as it may.

…

REMOVING STONES AND BUSHES. – The task of removing the stones and growth of shrub oaks, and other bushes, is immense, a ton’s weight of the former being on an average, generally taken off from 6 to 9 feet of square ground. In addition to inummerable stones of from ten to one or two hundred pounds weight, are larger stones, imbedded mostly in the soil, weighting several tons. These are taken out by digging away the earth around them and blasting; the object of the first blast being to open a seam, and then the second blast splits the whole mass into several pieces, and throws it out of its bed; the work being done generally in autumn or forepart of winter, when the stones may be loaded on a boat or ox-sleds and drawn to any place where they may be wanted.

Large quantities are laid up into massive walls from 3 to 7 or eight feet thick, and 5 to 7 feet high. The fences on this farm are already built for generations to come, with but trifling expense in occasional repairs. Hundreds of tons of these stones have been buried in ditches in the bog meadow and on the wet lands, for the purpose of drainage.” [p.105]

“My attention was directed to a field of 12 acres, which he took in hand a few years since, an old orchard, which had been in grass for a long time, the soil thin, and the field covered with stone-heaps. These were removed, the field plowed about six inches deep, and the stones brought to the surface in the operation, picked up and carted off.” [p.107]

FC102

French, H. F.

1855 “Letter from the Homestead” The New England Farmer vol. 7 no. 10 (Oct. 1855) pp. 462-463.

NOTE: The author compares his ancestral family farm in Exeter,NH which had been cleared of stone from years of labor with a newly acquired (1848) farm in Chester, NH which was extremely rocky.

“[p.462] At Exeter [NH] I have wrought, mainly on new land, till I bought my farm [in Chester,NH]…

There is hardly a stone to throw at a dog on the fifty acres. The buildings are all new there, the trees all young, and everything in order. But here, I return to a different scene [i.e. family “homestead” in Exeter, NH]. Fifty-five years ago [1800] this house was built, and the barn and sheds. All along during the century, from time to time, my father, who was one of the progressive farmers of his day, though a lawyer of large practice, was improving his farm. My first impressions of farming, are made up of laying heavy stone walls and blasting rocks. This was the great feature of the farm operations when I was a boy. To get a few acres clear of stones and well walled in, was the great thing. What was undertaken, was done in those days, and you have seen the smooth fields, and the big wall, seven feet high, round the barn-yard, built of stones many of them two tons weight each. It would make a cannon-proof fortification about Sebastopol. Then the fifty-acre cow-pasture, and several larger pastures for the young cattle, were all walled in, and everything made secure.

Stones or no stones, that is the question. I have thought of it a good deal, as every man should, especially if about to purchase a farm. “commentators differ” upon this, as most other subjects. One man says he would not take the gift of a rocky farm. He would have “easy land.” While another does not exactly see how one can get along at all, without stones in abundance, for walls and drains and divers other uses. Having had for some years a farm of each kind under my charge, perhaps a statement of the pros and cons may be useful to some of our readers.

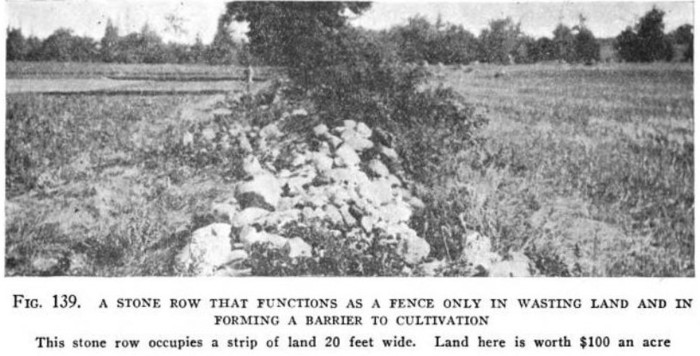

As to fences – a stone wall is doubtless the cheapest and most durable of all fences, and where stones are constantly working up in your fields and must be removed, no doubt this is the best use to make of them. But the objections to stone fences around fields and gardens are numerous. They occupy a good deal of land, not only by covering it, but their rough points, and the fear which cattle [oxen] have of touching them in plowing, prevents working within about two feet of the wall. It is a great labor which the crop will not repay, to dig up those spaces by hand, and so it generally happens that briars and bushes occupy them, offending then good taste of al beholders. Then again stone walls furnish excellent accommodations for vermin of all descriptions. …

On the whole, I think in most localities, especially where land is valuable, the balance of argument is not greatly, if at all, in favor of stone fences for our [cultivated] fields. For a pasture, there is nothing so cheap, so convenient, so reliable as a good fence. If it falls down occasionally by the action of frost, you are pretty sure to find materials close at hand for repairs. If, therefore, one could have just stone enough to complete his walls round his pastures, and a few spare ones for drains and the like, and clean fields and gardens, it would be the prettiest farm in the world. But Providence does not so order things. While I have actually been obligated to send to a neighbor’s farm in Exeter to beg stones enough to load a field roller, I should judge from the walls and fragments about the old place here, that the surface might be covered a foot thick if the stones were carefully spread again. And by the way, you remember how one Sunday this very summer, one of my Deven cows, educated in my smooth pasture at Exeter, was caught between two stones here in the pasture [Chester farm], ignorant as the poor thing was of such traps, and how she nearly tore her foot off. … The only wonder to me was, that there was a place in [p.463] the pasture where there was room enough for a cow to get her foot between the stones! [i.e. The author means the field was so rocky, he was surprised to find a gap between the stones.] Perhaps, however, such accidents are too rare occurrence, to form a serious objection to rocky pastures.

Stones are a great nuisance in plowing, in hoeing, in mowing, and indeed all other operations on the land. On my Exeter place, we grind our shovels and hoes, and they hold their edges for weeks. We set the plow at one end of the field, and it runs without stopping or breaking the furrow to the other. We grind our scythes, and they are only dulled by cutting the grass itself. Here, although our fields are cleared, and the boys have picked stones for a hundred years, every stroke with the hoe or shovel gives back the sound of a pebble on the steel, and the implements are soon blunted.

We use nearly double the team in plowing, and the plow groans and labors constantly, as if passing through a stone heap, and every new breaking up of the sward brings to light a few loads more of the hidden rocks. Clear your field as you will in a stony region, some round pebble will rake your scythe from point heel, every swath, and occasionally the point of a fast rock will break such a gap in the edge, as will send you groaning to the grindstone. And as to mowing machines, the effect of contact with stones with one of them is too painful to be more alluded to.

In this view, decidedly, I don’t like many stones on a farm. I never felt the want of them in Exeter, except for drains. …If I could find good land free of stones, I should vastly prefer it to what is called stony land. …

After all, there is much to be said in favor of the hard hill farms of this part of New Hampshire. The world does not produce finer apples than old Chester. They constitute the leading selling crop of the town, as indeed of the county generally. On these hills, where we find a pan so hard that we use a crowbar in digging a post-hole, and often find stones enough to nearly fill it when dug, an apple tree is almost sure to live and thrive.” pp.462-463

FC103

Baigrie, John

1839 “Description of a Farm in the Western Extremity of Eastern Ross, Ross-Shire [Scotland.]” Farmers’ Register v.7 no. 12 (1839) pp.759-764.

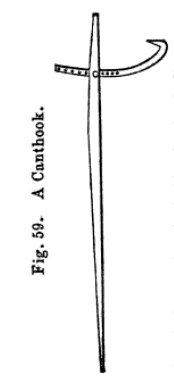

“[p. 760] Blasting Stones. – While the drainage was going on, men were employed to blast the large stones some of which lay on the surface, while other showed only a small portion above it, and many were not discovered until the field had got the first ploughing. These stones, the greater number of which would weigh several tons, were blasted with gunpowder to a size which would enable two men to lift the pieces into a cart. Such of the stones as were below ground, or had a part only buried, the contractor for the blasting was bound to clear around them, i.e. expose the whole of the stone to view, for the reason that, when the stone exploded, it might have room to fly asunder. When this operation is neglected, much labor and expense are lost. The expense of boring, blasting, and clearing the stones, including gunpowder, was fifteen pence per foot of bore, but latterly, by competition, was reduced to a shilling per foot. Many stones required thirty feet of bore to reduce them to a size fit for building stone fences, to which purpose they were to be applied.

Trenchin. – As the two fields intended for turnips and fallow contained several cares of uncultivated ground, chiefly covered with hazel, alder, and birch wood, these were trenched by the spade to the depth of sixteen inches, turning up all the stones except those required to be blasted. The draining and stone fences, going on at the same time, these stones were immediately carted off; the large for the fences, and the smaller ones to the drains. The expense of trenching varied considerably, according to the hardness of the soil, quantity of stones in it, and thickness of the brush-wood: in general, where all these prevailed the expense was fourteen pounds pre acre; when not covered with brush-wood, eleven pounds per acre.

…

Where ditches were not necessary for the purpose of carrying off the water, dry stone dykes or walls were built, both as being the preferable fence where cattle and sheep are pastured, and for the purpose of using the stones which were procured from the trenching and blasting. These dykes are three feet at the base, and carried to the height of four and a half feet of work tapered at the top to a breadth of ten inches and topped above all with a Galloway coping, or stones placed on edge, of about ten inches high, making the whole height five feet four inches. The expense per lineal ell [37 inches] including the driving of the stones, which the contractor for the dykes generally performs, ran from ten pence half-penny to a shilling. The stones, however, were near at hand which enabled the work to be so cheaply executed, and grass was found for the contractor’s horses on the unimproved ground. The price for building was sixpence per ell, and the different was **** for the carriage of the materials.” p.760

FC104

Encyclopedia Britannica

1823 Encyclopedia Britannica: Or, a Dictionary of Arts, Sciences, and Miscellaneous Literature; Enlarged and Improved. 6th Edition. Edinburgh: Printed for Archibald Constable and Company.

* A version of this entry first appeared in the 4th edition vol.1 issued in 1800 [?]

** Published in Scotland

“[vol. 1, p.357] 1. Of Removing Stones.

It is of the utmost importance to have land effectually cleared of stones, before undertaking any agricultural operations upon it; for by means of them there is frequently more expense incurred in one season, by the breaking of ploughs and the injury suffered by the cattle [oxen] and harness, than would remove the evil. It has also been observed that the soil round a large stone is commonly the best in the field. It may be considered as purchased at a low rate by removing the stone. At any rate, such stones must be removed before the ground can be properly cultivated. For whether a large stone occupy the surface or lie beneath it, but within reach of the plough, a considerable space around it cannot be stirred by that instrument, and is therefore useless. Even the rest of the field where stones abound must be laboured in a more slow and tedious manner, on account of the caution necessary to avoid the danger which they produce.

The stones which impede the improvement of the land are 1st, loose stones, or such as are thrown up to the surface by the plough, and 2dly, sitfast stones, which are either upon or immediately below the surface, but are of such a magnitude that they cannot be stirred by the plough. The first kind of stones may usually be easily removed by being gathered and carried off. When land is laid down for hay, such stones are often improperly thrown in heaps into the furrows, where they ever after continue to interrupt the plough, or dragged again by the harrows over the land. Instead of proceeding in this manner, they ought to be carried wholly off the field in carts at the driest season of the year, and placed in situations in which they may be rendered useful to the farm. In this point of view, stones are sometimes of considerable value for making concealed drains, or for making and repairing the roads through the farm, and also for the repairs of some kinds of fences.

The only writer upon agriculture who has in any case objected to the propriety of clearing land of small stones, is probably Lord Kames. In some parts of the south of Scotland, and particularly in Galloway, the soil is said to be composed in a great measure of gravel, and of stones of a smooth surface, as if worn by the running of water. After being ploughed, the whole surface of every field appears composed of loose stones lying almost in contact with each other. Some industrious farmers, with great labour, collected and removed the stones from a few of their fields with a view to their improvement: and the result is said to have been, that the succeeding crops were wholly blighted in the tender blade, and never came to maturity. The stones upon the surface were supposed to have prevent the exhalation of the moisture from the shallow and extremely porous soil which they covered: and they were also supposed to have contributed to foster the young plants, by reflecting powerfully from their smooth surfaces the sun’s rays in every direction around them: but when they were removed the soil in that bleak climate, became at once too cold and too dry for purpose of agriculture. The farmers, therefore, who had with so much toil and cost removed the stones from part of their lands, could think of on better remedy than, with equal toil, to bring them all back again, and carefully replace them upon their fields. It is added, that the soil immediately resumed its wonted fertility. The truth of this anecdote has never been contested; and there is no doubt that it has long been current in the South of Scotland, both previous to its publication by Lord Kames, and after that period, among a class of persons who are very unlikely to have been acquainted with his writings. It is possible that replacing the stones was the best remedy for the want of fertility in the soil which its cultivators had within their reach” but it is probable that they might have found it of more importance to have covered the surface of their land with a substantial coat of clay marl, or even with almost any kind of earth or clay, obtained from the bogs and swamps that usually abound in these countries, providing only they could obtain a quantity of lime to aid it. In this way, possessing land whose bottom was very pervious to moisture, they might obtain a soil suitable to every purpose of agriculture; whereas, in its present state, it must remain for ever unfit to be touched with the scythe.

With regard to large sitfast stone which cannot be removed by any ordinary effort, they usually either appear fully above the surface or are concealed immediately under it. For the sake of discovering concealed stones, it is said to be a custom of Yorkshire, when they intend to reduce land under the plough, in the first place, carefully to go over the whole surface with sharp prongs, which at the distance of every twelve or fourteen inches they thrust into the ground to the depth of above a foot, and wherever a stone meets the prong, they mark the spot with a twig, a bit of wood, or some other object. They afterwards trace all the marks, and remove every stone before they touch the land with the plough.

Concerning the modes which have been adopted for removing large stones out of the way of the plough; one of the simplest is the following: a pit or hole is dug besides the stone, 16 to 18 inches than the height or thickness of the stone. A number of men are then assembled, who tumble it into the pit. It is immediately covered up with a part of the earth that came out of the hole; and the rest of the earth scattered over the field, or employed in bringing to a level with the rest of the soil the spot where the stone formerly [p.358] lay. As the stone now remains at a greater depth than the plough can reach, it is no longer an impediment to agriculture. In performing this operation, however, the workmen attend to the nature of the soil, and take care that the weight of the stone do[es] not bring down the side of the pit, which might be attended with dangerous consequences. To obviate any hazard of this kind, it is always proper to have at hand a stout plank, which ought to be laid across the pit or hole, immediately under the nearest corner or edge of stone. With this precaution, a single man may usually perform the whole operation of burying stones or pieces of rock of very great size and weight.

By the above operation, however, the stones are utterly lost; whereas they may sometimes be of considerable value for fences or other buildings. When this is the case, they must be broken to pieces before they are removed. With this view it is to be observed, that a great variety of stones have some thin veins, which being found, wedges can be driven into them by large hammers, so that they may be easily broken. For such operation spades and pickaxes are necessary to clear away the earth, and a large and small lever to turn the stones out of the ground. Hammers and wedges are requisite, with carts to remove the fragments from the field. In the Statistical account of Scotland, vol. xix p. 565. parish of Maderty, we are told that ‘the Rev. Mr. Ramsay, the present incumbent, who occupies a piece of land full of sitfast stones, constructed a machine for the purpose of raising them. It operates on the principles of the pulley and cylinder, or wheel and axis, and has a power as one to 24; it is extremely simple, being a triangle, on two sides of which the cylinder is fixed; it can be easily wrought and carried from place to place by three men. A low four-wheeled machine of a strong construction is made to go under the arms of the triangle, to receive the stone when raised up. This machine has been already of great use in clearing several fields of large stones in this place and neighbourhood.’

It is evident, that the machine here described is only valuable for getting stones out of the way in the gross and unbroken; and, accordingly, we learn that stone fences are almost unknown in the parish of Maderty.

Where stones are valuable, therefore, and the operation of breaking them with hammers and wedges is found impracticable or too laborious, it will be necessary to blast them with gunpowder. To perform this operation properly, however, considerable experience is requisite; for it is said, that a skilful workman can in most instances, by the depth and position of the bore, contrive to rend into three equal pieces without causing their fragments to fly about. In time of war, however, the expence of gunpowder is apt to become very great. With a view to diminish the cost of that article, it has been suggested, that it is proper to perform the operation not with gunpowder alone, but with that article of a good quality, mixed up with about one-third of its bulk of quicklime in fine powder. It is said that this composition possesses as much force as an equal quantity of pure gunpowder, and it is even alleged, that the proportion of quicklime may be increased with advantage. How the strength of gunpowder should be so much augmented by the addition of quicklime, we doo not know. Perhaps it may add to the force of the explosion by undergoing a chemical decomposition of its parts, as it has of late been suspected, that this mineral is by no means a simple or uncompounded body.

Where a field is very greatly overrun with concealed stones, the most effectual method of getting quit of them, and of rendering it permanently arable, consists of trenching it wholly by spade. Nor is this always the most expensive mode of proceeding. The trenching can be done at the rate of from 3l. to 4l. per Scots acre, which is one fourth larger than an English acre, allowing at the same time the stones or their price at the quarry to the labourers. In this way, the expence of ploughing the field is saved. The soil is deepened to the utmost extent of which it is capable, and ca be laid out in the form most convenient for cultivation. In Dr. Anderson’s report of the state of agriculture in Aberdeenshire, it is said that the expence of trenching an acre to the depth of from 12 to 14 inches, where the stones are not very large and numerous, runs from 4d. to 6d. a fall, which is from 2l. 13s. to 4l. per Scots acre. Ground that has been formerly trenched, is sometimes done as low as 2d. per fall, or 1l. 6s. 6d. per acre. Hence, in consequence of the practice of trenching ground by the spade being not unfrequent in Aberdeenshire, workmen have become expert, and by competition have rendered the price extremely moderate. It is a wish that the same practice were more frequent in other parts of the country, as it would have the tendency to introduce a taste for the most correct and perfect of all modes of labouring the soil, and would also occupy a considerable part of the population of the country, in the most innocent and healthful of all employments, that of agriculture.” Pp. 357-358

FC105

Meigs, Henry

1883 “Farm of Hugh Maxwell, Esq.” The American Agriculturist vol. 2 no. 12 (Dec 15, 1883) pp. 342-343.

“[Nyack,NY] I found Mr. Maxwell’s farm of 110 acres bounded by the Hudson, well worth the visit. The whole was in excellent fence, neatly piled about 4 ½ feet high, forming fields of from 4 to 8 acres. The formation of these fences has used nearly all the stones which were on the surface of the land. And in this it would seem as if Divine Providence had caused the rocks to be distributed of the proper size for fencing. Had the pieces been much larger or smaller they would not have answered the purposes so well as they now do. If they had been planted two feet under ground, or had been piled in large masses, the labor of fencing would have been very greatly increased.” P. 342

FC106

Harper, Joseph M.

1829 “Report on Farms” American Farmer vol. 11 no. 36 (Nov. 20. 1829) pp.281-282.

“[Farm of John Kimball, Canterbury, NH] A good stone wall, from three to fifteen feet thick, is almost the only fence to be found about the farm. The wall is thick from necessity, in order to get rid of the stones. Some of it is very high, with flat stones on the top, projecting over into his pasture, from ten to fifteen inches; forming a good barrier against the intrusion of sheep, an object which every farmer knows to be very desirable, as ordinary stone wall is but a poor security against the invasions of this animal.

Mr. Kimball has about twenty-five acres of mowing, arable and orcharding, being all that his farm can afford by reason of the unevenness of the surface, ledges, fast and loose stones. This has been prepared with great labour; the stones are well cleared off, the surface, made smooth, the soil well mixed with manure, and thus made productive.” P. 281

“Farm of Amos Cogswell, Canterbury, NH] He has about twenty acres of mowing, tillage and orchard land, enclosed in two fields with stone wall. Both are well cultivated, the stones taken out, the land well manured and very productive.” P. 281

“[Farm of Col. Stephen Moore, Canterbury, NH] He has dug out the stone, laid them into good wall, and where stone was wanting, he has made a good fence of chestnut rails.” P. 281

“[Farm of Captain Moses Coffin, Boscawen, NH] His farm is mostly fenced with a good stone wall, for which he has an abundance of materials. Of this fact he appears to be well convinced, (as we had the best possible evidence,) he having drawn stone more than one mile, to fence a piece of pine land, which is destitute of this hard, valuable article for fence.” P. 282

FC107

Anon

“Culture of Stony Ground” New England Farmer vol. 7 no. 6 (June 1855) pp. 261

“Mr. Editor: - On looking into your paper, just come to hand, I find a correspondent inquiring in what manner `stony ground’ can be most advantageously tilled. My answer would be, first remove all the loose surplus stones within one foot of the surface, and then proceed in the cultivation as though they had never been there. Will it be said, that it be too much labor to do this? And, if the surface stones are once taken away, others will soon work up to take their place? Such has not been my experience. I know as fine fields for tillage, that were once as covered with a superabundance of such stones, as any other fields; and I cannot but think, that any apology for not removing them, must be the prompting of a spirit of laziness. To attempt to proscribe a form of plow or other implement, adapted to the cultivation of such land full of stones, would be a labor in vain. Better begin in the right way, and then labor will be amply rewarded. There can be no doubt that a portion of stones is beneficial to some crops; and that certain elements are added to the soil, by the dissolution and decay of stones, that improve it; but still, I do not think this improvement enough, to balance the inconvenience of having them in the way and use of the best constructed implements - such as the Michigan sod and subsoil plow – the horse hoe – and the best improved seed-planters and weeders.

An Old One Danvers [MA], April 10, 1855” p. 261

FC108

Yant, D.

1852 “Domestic Fish Ponds” Ohio Cultivator vol. 8 no. 10 (May 15, 1852) p.150.

“HOW TO MAKE A FISH POND, AND GET RID OF STONE. – I had on my farm a number of heaps of rough stone, not very nice to look at, and not very convenient to get around, nor very profitable. There were also several spring runs with deep gullies, across which it was desirable to have a road, so I hauled the stone into one of the gullies insufficient quantity to make a bridge, dug down the banks, and graveled the upper side and surface of the stone bridge, forming a clear pond of spring water. Into this I have put some choice varieties of fish, that are not apt to prey upon each other, so that when fully completed I shall have , instead of nasty stone heaps, and a deep gully over which I could not pass – first got rid of the stone – made a bridge – a fish pond of some eight square rods, from three to six feet in depth , and with very little additional expense can be made a convenient water place, the whole at the cost of some six or seven dollars in labor. How do you like it?

Mineral Hills, Tuscarawas Co. O. [Ohio] D. Yant.” P. 150

FC109

Holbrook, F.

1851 “Practical Husbandry” The Cultivator vol. 8 no. 1 New Series (Jan. 1851) pp. 35-38

“[Farm of Leonard Stone, Esq., Watertown, MA] The owner has for several years been clearing his tillage-fields of stones, which were formerly so numerous as to be much in the way of the plow. They have been sunk in the construction of drains, and thus the surface of about every acre of stiff land has been relieved of both stones and surplus moisture. The ditches for the drains are dug about three feet deep, and of convenient width to work in; in them, drains are first laid, six inches wide, ten inches high, of small cobble stones, and covered with larger sizes of the same; the ditches are then filled with small stones, to within one foot of the surface of the ground. A layer of shavings or tough sods is then put on, and the work leveled with loose earth. The drains thus constructed have stood from eight to twelve years, and still work well.” p.36.

FC110

Durand, L.

1851 “Farm Fences” The Cultivator vol. 8 no. 7 New Series (July 1851) p.244-245.

“[p.244] The subject of farm fences is one which every farmer should be interested in. Every farmer knows well that a good fence is what he likes to see around his fields, and those of his neighbors. There are but few of us who not suffered in years past by poor fences and breachy cattle – of course. As to the kind of fence to be built, all depends upon circumstances and location. Any kind of fence looks well, when well built and in good repair. Probably the most substantial and lasting of all farm fences, are built of stone. On most farms in New-England, more or less stone fences can be made.

But the manner in which fences are often built, is another consideration. We often see single walls laid up with only one tier of stone, and where they have been built for years they often have a zigzag or worm fence appearance, and how they stand at all, is a question. Often, where such fences are made, not one half of the stone are taken from the field, which is bad economy, to say nothing of the fence. Farmers should remember that when a field is cleared thoroughly of surplus stones, and the stones laid into good substantial walls, they have gained two important points. First, they have cleared the land for good cultivation, and second, they have a good fence, which, if well laid up, will last a lifetime. Walls four and five feet wide at the bottom, and as many feet high, with cap stones on top, projecting over three or four inches on each side, will turn sheep pretty effectively.

In many parts of Connecticut, old rail fences may be seen three or four feet high, while the stones are so thick that you may travel on them from one field to another. I consider it the most miserable and shiftless economy in the way of fences and cultivation that the Connecticut farmer has yet accomplished. The most durable rail-fence, to my mind, is the old `Virginia worn fence.’ When this fence is well laid up, six or seven rails high, with long poles or riders staked on top, hardly any wind will level it to the ground. You cannot work up to this fence quite so close, as to a straight fence. But for pasturing or mowing, it takes up but little or so more ground than the post fence. The posts of the straight fence which I built ten and eleven years ago, are now rotting off, and the fence is falling down. Some farmers say that fence posts will last double the time by setting the posts top-end down, but having never tried it, or never seen it tried, I cannot say as the fact.

Post and board fence is built by many farmers, and it makes a much neater fence than rails, and is often quite as cheap, and much lighter in construction. Wire fence [p.245] is now talked of, and some fence of this kind has been built, and if it be lasting, and the weather does not affect the wire, I think it will come into general use, especially on the western prairies where timber is scarce. I have been told that a cheap composition of coal-tar laid over the wires, will prevent rust or any action of weather on the wire. Where posts can be made of stone or Iron, and the expense will admit of it, this fence must be lasting. A prairie farm fenced with wire, would make a grand appearance, as at a short distance nothing would be visible but the posts. But some time must elapse before this fence can be thoroughly tried as to durability.

L. Durand. Derby, CTMarch 12, 1851.” P. 244-245

FC111

Anon

1850 “Notes on Massachusetts Farming” The Cultivator vol. 7 No. 1 New Series (Jan. 1850) pp. 40-42

“[p.40] On the farm Mr. Harvey Dodge, Sutton [Massachusetts], we witnessed some valuable improvements. The farm lies on a large swell of land, which is naturally very rocky, and quite wet. It was originally divided into very small lots, many of them containing only two acres each, and fenced with stone walls. One object of these small [p.41] divisions was probably to get rid of the stones, which had to be removed from the soil before it could be worked. Some idea of the quantity of stones may be formed from the fact that these walls were made from four to six feet wide and four feet high. The foundations of many of them not being properly laid, and the materials not of the best kind for permanent walls, they had in several instances settled down and flattened out, till they occupied much more room than at first.

When Mr. D. took possession of the farm, a few years ago, he soon discovered that it had two radical defects, which he determined to remedy. The first was the loss of land by the numerous old walls, and the inconvenience of working the small lots; and the second, the want of drainage to the soil. In obviating the first difficulty, he adopted a plan by which he, in a great degree, obviated the second. He sunk the old walls, and the trenches where they are buried have become drains! He has in this way turned a large part of his farm into beautiful fields, of from 12 to 18 acres each. Where the walls on the lines of the present division were good, they were left, where they were not good, they were rebuilt in the most substantial manner. The walls were sunk so low that the plow passes over without disturbing them. The mode of sinking the walls was by digging deep ditches close along side of them, and then throwing the stones in. The ditches were filled to a level with the surrounding ground, with the earth taken out, and the remainder is used in filling hollows about the fields. The effect of the drainage is already apparent in the sweeter nature and more abundant growth of grass, in the better and surer crops of grain which the land produces, and in the more healthy and thrifty growth and increased productiveness of fruit trees.”

FC112

Saunders, William

1888 “Experimental Farms. Reports of the ... for 1887.” (Appendix to the Report of the Minister of Agriculture.) Sessional Papers vol. 6; Sessional Paper No. 4D. Ottawa: Maclean, Rogers & Co.

“[Township of Nepean, Carleton County, Ontario - 3 miles form Ottawa] On taking possession of this farm, which comprises a number of small holdings, the dividing fences were found to be well packed with surface stone collected from the fields; there were also many heaps at different points and large boulders scattered over the surface. While this farm is much less stoney than most of the land in the immediate neighbourhood of Ottawa, nevertheless much labour and expense was entailed in clearing the field of surface stone. These stones have been got together in piles, a part of them has already been used in improving the roads on the farm, and the remainder will all be useful for a like purpose.” p.3

FC113

Stephens, C. A.

1912 When Life Was Young: At the Old Farm in Maine. Norway, ME: The Old Squire’s Bookstore.

“There were now brakes to cut and dry for “bedding” at the barn, bushes and briars to clear up along the fences and walls, and stone-heaps to draw-off, preparatory to “breaking up” several acres more of greensward.” P. 297

FC114

Allen, Richard L.

1847 A Brief Compendium of American Agriculture. 2nd Edition. New York: Published for the Author by C. M. Saxton.

“It is a subject of frequent remark, that the soil underneath, or in immediate contact with some stone walls, which have been erected for a long period, is much richer than the adjoining parts of the same field. This difference is probably due, in some measure to the slow decomposition of important fertilizers in the stone, which are washed down by the rains and become incorporated in the soil. The removal of stones from a fertile field, has been deprecated by many an observing farmer, as materially impairing the productiveness. Beyond the shade thus afforded against an intense sun, protection from cold winds, their influence in condensing moisture, (and the beneficial effects which perhaps ensue as in fibrous covering,) the difference may be attributable to the same cause.” P. 46

FC115

James, C. C.

1893 “The Dairyman as a Manufacturer.” Sessional Papers vol. 25 pt. 5, Sessional Paper no. 16. Toronto: Printed for Lud. K. Cameron, Queen’s Printer by Warwick & Sons. Pp.161-166.

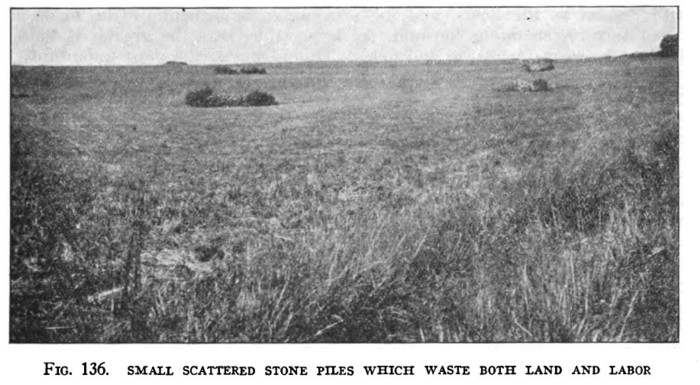

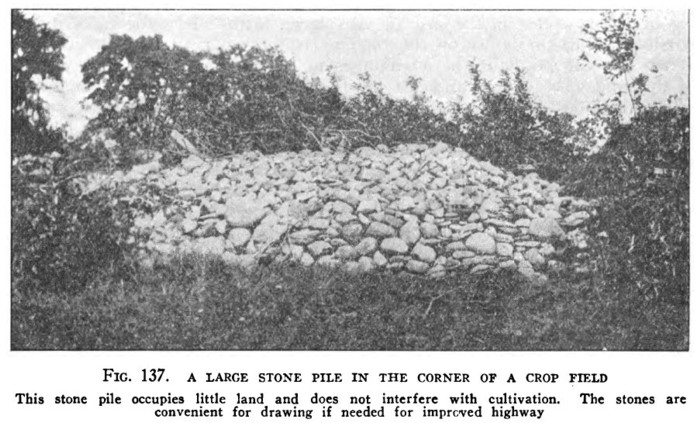

“Capital is not all utilized when owing to lack of drainage the under-acres of the farm are contributing nothing, when the weeds are fighting with the domesticated plants for limited supply of available food, when unsightly stone piles lie in the centre of fields instead of at the bottom of good macadam roads, when crooked and unnecessary fences sprawl about in all directions …” p. 163

FC116

Brown, Simon (ed.)

1861 “Clearing Fields by Burying Stones” The New England Farmer vol. 13 no. 7 (July 1861) pp.335-336.

“[p.335] CLEARING FIELDS BY BURYING STONES.

An exchange has the following on the above subject:

`With regard to the disposal of stones, I think there is one rule of universal application, which is this: On all land that is not so rocky underneath as to make digging expensive, never take a stone that is not wanted for wells, or for some other special purpose, but dig holes and place them in so that they shall not come nearer than eight or ten inches of the surface. This can be done as cheaply as they can be carted off and piled up in some other place. There are, at least, for advantages in this process.

1. The surface is relieved of them, so that they are out of the way of cultivating.

2. If not too far below the surface, they attract moisture, and are especially valuable where deep-rooted plants are cultivated in times of drought. Fruit trees flourish finely over them.

3. They are storehouse of heat, warming the soil about them, and the young roots that penetrate it, and acting like bottom heat in a forcinghouse.

4. So much of the land as is dug over to receive the stones is thoroughly trenched, and will feel it influences for many years, whether it is cultivated or kept in grass.’

We object to articles like the above, and believe that the writers are doing serious injury to after generations, by suggesting such wasteful painstaking. The idea of burying stones, and at eight to ten inches from the surface, so as to prevent full surface plowing and to entirely do away with the possibility of easy subsoil plowing, cannot be endorsed. The surface should be relieved of them by their removal, unless they can be placed in under-drains immediately, and at least to a depth of thirty inches below the surface. As to their attracting moisture when at proper depth, this they will do by extracting it form the soil. We do not believe that a soil full of stones is any better for fruit trees than one without them. Nor do we believe that stones should be viewed as storehouses of heat, warming the soil about them etc., they only become heated by cooling the soil. The fourth item of the above, however, we fully believe in, viz., “that the digging of the soil for the removal of stones, or for any other purposes, materially benefits it. – Working Farmer.

That portion of the above article commented upon by the Working Farmer, was written by us and published only two or three weeks since, in this paper. It was prompted by an actual experience of many years, is sound in doctrine, and an article that we have no desire to recall. If agricultural editors would spend more of their time in the field and less in the closet, their teachings would be more reliable than they now are.

In the first place, we are charged with “wasteful painstaking,” for stating that it is as cheap to [p.336] sink stones not wanted for other purposes, as to dig, cart and haul them off on a drag. On all such land, as we specially defined, there is not one operator on ten, on our knowledge, but will agree with us. It has been so decided in some of the best farmers’ clubs in New England.

Our first postulate was, that when sunk, they are out of the way on the surface. Who will deny that? The second, that rocks below the surface are especially valuable when deep-rooted plants are cultivated in times of drought. If the learned editor of the [Working] Farmer had dug as much as we have on a rocky soil, he would have learned what most boys of eighteen know, on our rough farms. Fruit trees do not flourish half as well on our soils without stones as they do on the rocky lands. That is the common opinion here. Thirdly, buried rocks are store-houses of heat. If a stone is placed upon a coal fire it becomes heated – let both remain for a time and the coals will be ashes, or black and cold, while the stone remains too hot to be touched. So the rock in the soil stores up the solar heat, and imparts it as much more slowly than the loose, surrounding soil, that it is actually a storehouse of heat. The stones below are valuable in other respects. The rains reach them, dissolve some of their mineral matter, and prepare it for use of plants. The roots themselves understand this better than theorists, as is evident by their clustering in great numbers about stones which are beneath the surface, where they not only find food, but moisture and warmth. The Professor’s idea of subsoiling on a large portion of our farms, we think erroneous. On such land as we referred to, one might as well think of subsoiling on the peak of the Grand Monadnock itself; the very difficulty of the sinking of stones is generally that of digging the holes, obstructed as the spade often is at every blow.

We always read the Working Farmer with pleasure, and we believe with profit, and quite often illumine our columns with the clearly-expressed thoughts of its editor,- but we cannot recall deliberately-expressed opinions, which have been formed upon actual manipulations extending through many years, founded upon philosophical principles, and sanctioned by the best farmers in our knowledge.” Pp. 335-33

FC117

Kimball, Isaac

1857 [Letter to Moody Hobbs, Esq. from Isaac Kimball, Temple,NH, January 6, 1857] Transactions of the New HampshireState Agricultural Society for the year 1856. Concord [NH]: Amos Hadley, State Printer.

NOTE: The farm was purchased in 1831. It is unclear from the letter as to exactly when the activities described below took place. Kimball had entered his farm for a premium contest. The committee for the Society was unable to visit the farm to inspect it for the contest. Instead they sent a list of questions as a substitute for the onsite inspection. The letter is a reply to those questions.

“[p.105] I have found it necessary to use a large per cent of muck [to make manure]; and have opened ditches for this purpose, of various dimensions, some of which were four feet wide by from two to six feet deep; these have been filled with stone to near the surface, then covered with turf and mud or other [organic] matters, and sown with grass seed. In one instance a ditch was dug ten feet wide, and some ten rods [160.5 feet] in length, for a cart-way and filled with stone. The stone[s] were brought from the fields adjacent, some were blasted, others dug from the fields. Old walls removed, and unsightly heaps, long a nuisance, all thus congregated, probably to be seen no more.

Some fields have been cleaned of stone, by removing them to the base of a hill-side and erecting a heavy upright front wall, removing the soil from the rear and filling with stone; then replacing the soil, making a level surface for cultivation. A large amount of stone has been removed to low, wet ground in an adjoining pasture, the stone covered slightly with soil and gravel, and sown down to grass. The removal of stone [p.106] by blasting and otherwise, has been among the most expensive items of improvement.” Pp. 105-106

FC118

Adams, James O., Secretary

1877 [Minutes of the Board of Agriculture meeting in Hollis NH December 27, 1877] Seventh Annual Report of the Board of Agriculture, for the Year 1877. Concord [NH]: E. A. Jenks, State Printer.

“Mr. Walker then took up Drainage, showing that much of the land now to wet for practical purposes can be brought into a fair state of cultivation by draining, and recommended farmers to clear away the rock-heap so long used for growing briars, and use them for under-draining the land.” P. 109

FC119

Walker, Joseph B.

1876 “The Hay Crop.”Sixth Annual Report of the Board of Agriculture for the Year 1875-6. Concord [NH]: E. A. Jenks, State Printer. Pp. 253-265.

“[Concord, NH] Should it be here intimated that half-buried boulders and stumps and rock-heaps often opposed the use of these implements [i.e. hay cutting machinery], it may very properly be said in answer, that it is part of their mission to bring about the removal of such impediments, and compel us to do things we ought to have done years ago.” P. 261

FC120

Walker, Joseph B.

1875 “The Soil.” Fifth Annual Report of the Board of Agriculture for the Year ending June 1, 1875. Concord [NH]: Charles C. Pearson, State Printer. Pp. 93-108.

“[ConcordNH] I suggest, therefore, as the first step to be taken in the improvement of very many of our fields, the removal from their surfaces all obstructions to a profitable vegetation. One may as well raise tame grass as wild bushes, and occupy his ground with corn or wheat or potatoes, as with carefully constructed rock heaps, belted with flourishing growths of weeds. Those last may look very fine from an esthetic standpoint, but, in an agricultural view, they are as ugly as sin. They utter mute accusations against their owner, which would, if spoken by his neighbors, expose them to the penalties of slander. Nigh and day, year in and year out, they proclaim him indolent, wasteful, shiftless, and a firm believer in the popular doctrine that `farming don’t pay.’” p. 98.

FC121

Poore, B. P. & F. B. Eaton (Compiled by)

1885 Sketches of the life and Public Services of Frederick Smyth of New Hampshire.Manchester, NH: John B. Clarke, Printer.

“In 1827, the father of Frederick purchased the farm and house afterwards occupied by the Rev. Abraham Wheeler, a few rods east from the residence of john Lane, Esq., and removed there with his family. Whatever may have been the hardships incident to the life of a New Hampshire farmer’s boy, young Frederick accepted them without a murmur. As an instance of his industry, it is told that when he was a slender lad, he yoked up the cattle during his farmer’s absence from home, and cleared the rock-heaps from a mowing field, working so steadily that he brought on severe headaches, and had to take a week’s time to finish the job in.” p.7

FC122

Wiggins, Francis S.

1840 The American Farmer’s Instructor, or Practical Agriculturist. Philadelphia: Orrin Rogers.

“[The Common Horse Rake] When small obstructions occur, the handles are depressed thus causing the teeth to rise, and the rake passes freely over. Large obstructions, as stumps and stone heaps, require the rake to be lifted from the ground.” P. 450

FC123

Russell, Benjamin S.

1854 [Letter by Benjamin S. Russell, Towanda PA, December 12, 1853] First Annual Report of the Transactions of the PennsylvaniaState Agricultural Society. Harrisburg [PA]: A. Boyd Hamilton, State Printer.

“[p.491]About the middle of October I saw the field, for [p.492] the first time after harvest; it was then quite stony and looked rough. Since then upwards of fifty wagon loads of stone have been taken off, and a large number of stumps have been grubbed out, and are now lying in a heap in a corner of the field. After the survey had been made, I counted the stumps remaining, and found them to be three hundred and sixty-three. Mr. Mason measured the ground around several and averaged the whole, and found the waste ground to measure, as stated in his certificate, one acre and twenty-two perches. Had the stone heaps which were there in October, been three at the tenth instant, I do not hesitate in saying that, in my judgment, it would have reduced the actual land cultivated to six acres, or perhaps a trifle less.” P.491-492

FC124

Agricola, P.

1824 The New York Gardener, or Twelve Letters, from a Farmer to His Son, by which he describes the Method of Laying Out and Managing the Kitchen-Garden. Albany: Published by Daniel Steels & Son.

“Those heaps of stones piled about the fields, must be removed, and made into fences.” P. 8.

FC125

Stephens, Henry

1844 The Book of the Farm. Edinburgh & London: William Blackwood and Sons.

“On every kind of land the small stones lying on its surface should be gathered by the field workers and carted off for the use of drains, or broken into metal for roads. It may happen that the throng of other work may prevent the assistance of horses and carts being given for this purpose, in which case the stones should be gathered together in small heaps on the furor-brow of every other single ridge; but in doing this, it should be remembered that these heaps occupy so much of the ground, and, of course, prevent the growth of so much grass, that, on this account, it is much better practice to cart them away at once of practicable. When carts are used the stones are thrown directly into them; whereas in making heaps, the stones require some care to be put together, and, of course, waste time, and they have to be removed after all. Some farmers are regardless of gathering the stones from any of their fields, even from grass-fields which are in pasture; while all acknowledge that fields of grass which are to be made into hay ought to be cleared of stones to save the scythes at hay-time.” P. 807

FC126

Lane, Alfred C.

1907 Report of the State Board of Geological Survey of Michigan for the Year 1906. Lansing,MI: Wynkoop, Hallenbeck, Crawford Co., State Printers.

“The cleared fields are, in general, surrounded by piles of stones that have been gathered from their surfaces, and in part built into walls.” P. 51

FC127

Eliot, Charles W.

1904 John Gilley: Maine Farmer and Fisherman. Boston: American Unitarian Association.

“[SuttonIsland] The piles of stones which he heaped up on the bare ledges remain [p.48] to this day to testify to his industry. One of them is twenty-four feet long, fifteen feet wide, and five feet high. In after years he was proud of these piles, regarding them as monuments to his patient industry and perseverance in the redemption of this precious mowing field.” P. 47-48

FC128

N.H. Journal of Agriculture

1862 “Economy of Fences.” New England Farmer vol. 14 no. 12 (Dec 1862) pp.546-547.

“[p.546] There are very few farms that would not be benefited by the drainage effected by casting the stones regularly into ditches opened for the purpose each [p.547] year as it became necessary to haul them off. These of course are not equal to tile drains, but they serve two purposes, and they are very useful. Probably half the stone fences on many farms had better be sunk in this way. We know of scores of acres of wet swampy land, always late because wet, and of endless runs, where huge piles of stone lay in unsightly confusion on the borders and all about.” Pp. 546-547

FC129

Smith, Jonathan

1900 The Home of the Smith Family in Peterborough, New Hampshire, 1749-1842. Clinton [MA]: Press of W. J. Coulter

“[p.123] In the spring of 1808, he took his sons William and John, aged seven and five respectively, down to a field of some six acres west of the barn, which has always within memory of the writer borne the name of “The Gap,” no one knows why, and set them to [p.124] work picking stones. If their descendants can judge from the number and size of the heaps they left there as monuments of their youthful toil, their task was neither short nor an easy one. The younger boy in his old age told one of his children how his father promised them a small reward in money for a certain number of heaps…

It was during this period of Jonathan Smith’s ownership that the farm was cleared of stones and the fields and pastures inclosed by stone walls. Many of the double walls, some of them six to eight feet thick, were built by him.” Pp. 123-124

FC130

Whittier, Phinneas

1883 “Lessons from my Experience in Orcharding.” Twenty-Sixth Annual Report of the Secretary of the Maine Board of Agriculture, for the Year 1882. Augusta: Sprague & Son, Printers to the State. Pp. 260-267.

“[p.260] In passing through our State one cannot fail to notice a great difference in the appearance of the farming community. In sections favored with rich alluvial soils, and on upland possessing a good soil comparatively free of rocks, the farmer who does not appear to be in comfortable circumstances is an exception. In other sections with an equally fertile soil, but so encumbered with rocks that it costs more to prepare it for cultivation than the land is worth after it is prepared, the farmer who is prosperous is the exception. We can ride many miles over our hills, through the best of orchard lands, and see deserted farms turned out to pasture or left to grow up to bushes, their former owners gone west or into more profitable business. Others there are where a hard struggle is still continued but all the signs about the farm and buildings point to a failure sooner or later. On such farms, where improved machinery cannot be well used, the high price of labor bears heavily, and this with decreasing fertility, and the competition of the West growing stronger every year, farming in the old way on such soils a very discouraging business.”

“[p.261] I confess I can see but one way that such farms can be made a source of profit and comfort to the owners and that is by making fruit farms of them in connection with sheep raising, for I consider sheep the best help we can have in cheaply keeping an orchard in the best condition. We can come nearer competing with the West in fruit raising than in any thing else. We can have good thrifty trees and luscious fruit where the rocks lie undisturbed in the soil, and the full blood merinos lie around enriching the soil and waiting to give us their valuable fleeces. If it is desired to free the soil of rocks, it will require only a small area, comparatively, for one acre of orchard well taken care of will be more profit than many whole farms of one hundred acres now are.” pp.260-261

FC131

Shaler, Nathaniel Southgate

1895 The Geology of the Road-Building Stones of Massachusetts with Some Consideration of Similar Materials from Other Parts of the United States.Washington: Government Printing Office.

“[p.310] It may be noted that there is a collateral advantage arising from the use of these erratics, which consists in the fact that, so far as the fragments occur in the form of field stones, they are at present an incumbrance to the earth – an obstruction to the tillage of the fields. A large part of the agricultural [p.311] labor which has expanded in Massachusetts has been given to the task of gathering these pebbles and bowlders from the ground to be tilled, the materials thus removed being accumulated in the stone walls and heaps which make so conspicuous feature in the farming districts of most glaciated areas. So far as this waste can be utilized in road building, the process is beneficial to the conditions of the fields and helpful to the interests of the agricultural class. At least three-quarters of the stone walls in Massachusetts have not been built with the object of dividing the tillage areas, but to get the stones out of the way of the plow. These fences are, indeed, a very general obstruction to the economical care of the earth. If the plan is adopted of converting this obstructive glacial waste into road material, and the method is followed for a century to come, the result will be a noteworthy increase in the value of the farm lands in the Commonwealth.” Pp. 310-311

FC132

Maine Board of Agriculture

1873 Eighteenth Annual Report of the Secretary of the Maine Board of Agriculture for the Year 1873. Augusta: Sprague, Owen & Nash, Printers to the State.

“It is a common sight to see long ricks of rocks tumbled up where it was convenient at the time to leave them, and where, perhaps, it is designed `at some convenient season’ to build a wall. They not only encumber much ground, but harbor bushes, weeds, and vermin, all of which are injurious to the farmer’s interests. It is also too common a sight to see fields dotted up with stone heaps, small and near together, with now and then a big stack, the accumulation of years from adjoining grounds. Instead of cumbering the surface with their unsightly presence, how much benefit they might confer if put into underdrains, the only proper place for cobble stones on the farm.” P. 225

FC133

Blaikir, Francis

1839 “On the Husbanding of Farm-Yard Manure, and on Other Rural Subjects.” Farmers’ Register vol. 7 no. 7 (1839) pp. 401-406.

“Mending the roads is sometimes used as a plea in extenuation of the injurious practice of picking the stones off the land; but I consider the plea inadmissible, because where there are many gravel stones on the surface, it is a sure indication that a gravel pit may be opened to an advantage at no great distance; but a still greater objection rests in the injury the land sustains from such treatment, particular light soils, the staple of which is weakened, and the intrinsic value reduced in a very material degree, by having the stones picked off; indeed I affirm, that no stones should ever be picked off sandy or gravelly soils, (and but seldom from any other description of soils,) unless when the stones are so large as to impede the progress of the implements necessary to be used in the cultivation of the soil. Clovers and grasses intended to be mown should always be rolled down at proper season, after the larger stones are picked off.

It is a disgusting practice, and cannot be too severely censured, to pick the field stones into heaps in the fields, and there allow them to lay, as frequently the case the year round. This practice is unpardonable in the highly cultivated and justly county of Norfolk, a county to which most others in the Kingdom look up to for example. Yet, notwithstanding the general proficiency of the Norfolk farmer, I may justly apply to them the adage of “use is second nature,” (let it be remembered I speak in general terms, for there are very many exceptions) in respect to the stone heaps; for the farmer rides over his fields amongst those heaps of stone with seeming unconcern , as if unconscious of the injury he has sustained by having had the stones picked off his land in the first instance, and afterwards by their being left in heaps in the fields to destroy the herbiage they lay upon.” P.406

FC134

Shull, Josiah

1870 [Remarks of Hon. Josiah Shull] Transactions of the New York Agricultural Society, with an Abstract of the Proceedings of the County Agricultural Societies. Vol. XXIX (1869). Albany: The Argus Co.

“[p.747] Where a farm contains field stone of a proper size for laying into a wall, this material can be used to a good advantage. In estimating the cost, it will be assumed that every good farmer should clear his farm from all such stones as will be a hindrance in plowing and putting in the crops. In this case he naturally places them in convenient piles. Instead of piling, he should haul them to a line of fence, which expense will cost extra from piling, say twenty-five cents per cubic yard. Making the fence two feet wide on the bottom, one foot on the top and four feet high, will require three and two-thirds cubic yards to a rod in length. The cost will be as follows:

[p.748]

For delivering stone for one rod of fence ……………………………$0.82

Laying them in wall ……………………………………………………75

-------

Making a total cost per rod of ………………………………………..$1.57

When ledge stone ca be obtained at not to exceed three miles of hauling distance, the dimensions of the wall being the same as above, the cost per rod, allowing for b[r]eaking from quarry, twenty-five cents per cubic yard; for hauling $1.25 per cubic yard, and for laying in wall, twenty cents per cubic yard, will be as follows:

For breaking ground per rod of fence ……………………………….82

Hauling and delivering stone …………………………………………$4.58

Laying in wall ……………………………………………………………73

------

Making a total cost per rod of ………………………………………..$6.13

If the ledge be on the farm the cost will be much lessened in expense of hauling as follows:

For breaking ground per rod of fence ……………………………….82

Hauling ………………………………………………………………$1.64

Laying in wall ……………………………………………………………73

------

Making a total cost per rod of………………………………………..$3.19”

FC135

Kelsey, Jno.

1860 “Farm Improvement” The Cultivator vol. 8 no. 4 (Apr 1860) pp. 122-123.

“[Prospect Farm, Bucks Co., PA] I also laid out a new farm road, which began at my wharf on the Delaware Division of Pennsylvania canal, (the canal being the eastern boundary of the farm,) and passes by the barn and by all the fields to the west end of the farm, where said road crosses the creek. I have built a large bridge of stone side walls, and cover the aperture for the water with stone, and then continued the side walls on upward, and the space between I filled with stone which I picked from the fields. The bridge is passable thought not finished, and never will be until raised up to a level with banks on both sides of the creek, and as long as any offal stone remain on the farm and the bridge is unfinished, there is a place to dump them.” P. 122

“P.S. I find on looking over the above article, I have forgotten to say anything of the amount of stone I have removed and the manner of doing it. In plowing any other than a sod, I place a grubbing-hoe axe downward in the coulter-hole in the plow beam, and then say to the plowman, take out every stone of sufficient size to disturb the plow, and if he finds any too large, I have him mark the place, and take them out afterward. By this method I cleaned nearly all the farm of stone – in all some 300 or 400 perches, nearly all of which are first rate building stone, and many of them so large as to require blasting before they could be removed – in addition to all of which, I grubbed innumerable loads of briers and elders from along the fences.” P. 123

FC136

Rogers, William [pseudonym]

1907 Erecting and Operating: An Educational Treatise for Constructing Engineers, Machinist, Millwrights and Master Builders. New York: Theo. Audel & Company.

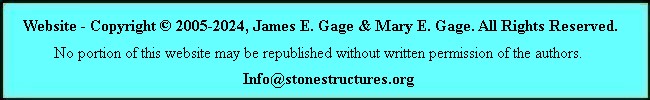

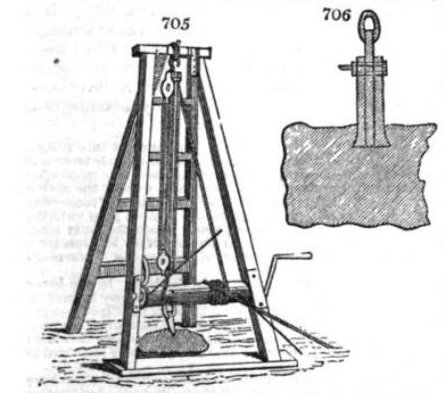

“Fig. 56 is a rock-lifter, by means of which one or two men “pumping” on the end of a 10 or 12 foot ash lever, can lift heavy rocks, pull tree-stumps, etc. A stirrup hanging from the end of the lever engages with the teeth of a ratchet wheel on the block axle, so that, with each stroke, the wheel is pulled around two or three teeth, and the sprocket wheel shortens the “bight” of the chain, thus exerting an accumulated force in lifting. The ratchet wheel is prevented from slipping by means of a pawl or “detent” on its opposite side.” P. 83

|

FC137

Platt, George F. et al

1873 “Clearing Rocky Land” Sixth Annual Report of the Secretary of the Connecticut Board of Agriculture 1872-73. Hartford: Press of Case, Lockwood & Brainard. pp. 116-148.

[NOTE: This consists of Mr. Platt’s paper on “ClearingRockyLand’ along with a question & answer / discussion which follow the presentation of the paper at the meeting.]

“[p.116] [Milford CT] My experience in clearing land of rocks and stones is confined entirely to our own farm, which consists of 100 acres, and is situated between two and three miles from Long Island Sound.

There is a belt of from one to two miles wide along the shore, the soil of which is generally light and free from stones and rocks, except as they occasionally crop out in ledges.

Our farm is back of this belt and elevated somewhat above it. The soil is a dark loam, six or eight inches, than a yellow loam three feet deep, almost free of stone, below that a hardpan eight or ten feet, then rock. All the wells in this vicinity are dug into this rock, which when blasted out makes excellent stone for building purposes. The rocks and stones on the surface are entirely different from this great underlying rock, being hard and heavy, with the corners all rounded off, looking as if they had been rolled and tumbled considerably in the early ages of the world.

There are enough rocks and stones on this and the neighboring farms to fence them into three acre fields, making single walls.

[p.117] When mowing machines first came into use, our meadows, cultivated land, and pastures were all encumbered with small stones and rocks too large to be removed easily, the intermediate size having been removed by my ancestors. We saw at once that in order to have the mower work well, it must have a smooth, unobstructed surface, and began at once to pick up by hand and cart off the small stones, and to roll out the smaller rocks with oxen, and raise the large ones with a Lyon rock lifter, which was owned in the neighborhood.

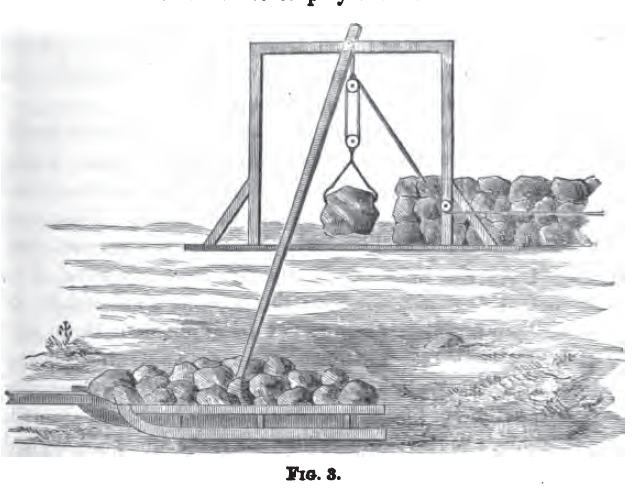

Our practice has been to lift the rocks to the surface and leave them till winter when they are easily drawn off on a stone boat, taking a time when the ground is thinly covered with ice or snow.

We have this way cleared one or two fields yearly, using the stone for walls, frequently taking up old crooked rail fences and putting walls in their place.

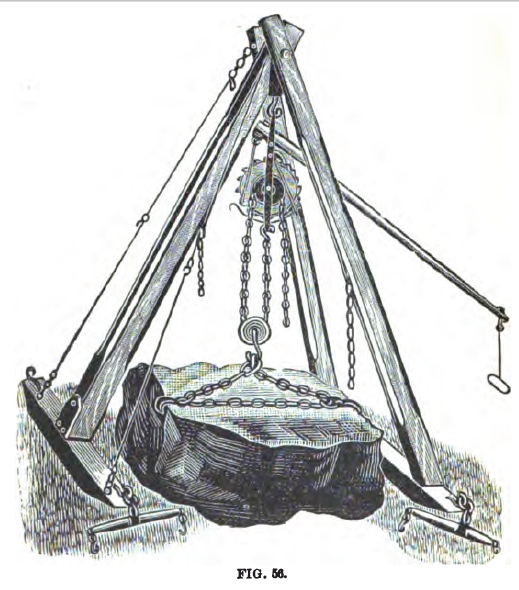

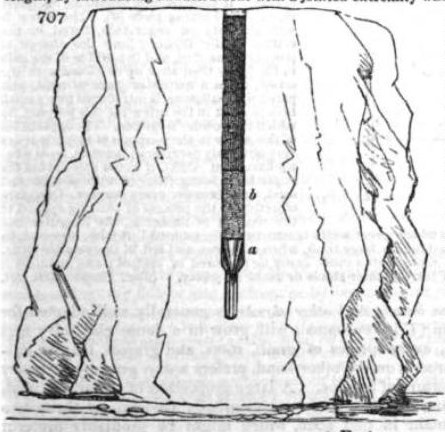

It is rather slow work to lift rocks with the Lyons machine, fifteen rocks being a good days works for two men; other machines may by using oxen work faster, but I have not used them. The past season I have used a simply contrivance for lifting and rolling out rocks, the idea of which was suggested to me by an illustration of a stump puller I saw in the Country Gentleman last year. It is so simple, cheap and easily made, and so efficient that it would, I feel confident, come into quite general use among farmers owning rocky farms, if they knew its value, and understood how to construct and operate it. It is difficult to describe a thing of this sort on paper so that it will be understood, but I will try to make it as plains as possible. It consists (fig.1,) of two upright pieces of light, strong wood, ten or twelve feet long, bolted strongly together at the top, in the form of the letter A, giving them a spread of four feet at the bottom; a cross piece of wood and a long bolt connecting the two, three or four feet from the top; make it strong by bracing and tying it. On one side of the top of the A is hinged and iron rod, six feed long, on the lower end of which is a large link, the top of which is wide, and the bottom narrow, so that when a chain is put through and dropped into it, it clasps the chain. From the top of the A, drawing from the [p.118] side opposite to that on which the rod is hinged, extends a chain forty feet long, passing under the cart, and fastened to the axle or tongue. The reason for drawing from a cart is that the draft is so high that otherwise oxen could not draw much. I have used large rope which I happened to have, two inches in diameter, instead of this long chain, but I think a chain made of rods, four feet long, would be the cheapest and best to draw by. A strong chain to go around the rock completes the concern.

To operate it place the A near the rock, leaning slightly over it; put the chain around the rock, having the noose on the side of the rock opposite the machine; pass the free end of the chain through the clasp link on the lower end of the rod, and start the team. As the A assumes the perpendicular and leans from the rock, the lifting power is enormous; it not only lifts or rolls the rock but draws it sidewise, taking it one side of the hole. It is generally necessary to back up the team and set the A up again, moving it farther from the rock and giving a second pull in order to get the rock entirely out.

As will be observed it lifts the rock up, whereas in rolling out rocks by the use of oxen, with a simple chain, the rock is drawn against the earth, and much force wasted, especially if [p.119] the rock is deeply imbedded. I have used this contrivance to clear the rocks from five acres, the past autumn, and I speak from experience when I say it works quickly and well. I can commend it to my brother farmers, as a simple, cheap and efficient rock lifter, one that is not patented, and therefore free for every one to make and use.

Mr. Gold. Perhaps I am entitled to say a word from experience as well as anybody else, in regard to moving rocks. I have used almost all the machines that have been about for this purpose. The Lyon Rock Puller, to which Mr. Platt refers, with which many of you are acquainted, exerts tremendous power, but it is very slow in its operation. I tried it and discarded it, because it was too slow and tedious. The Bolles' Rock Puller, I have used with very great success and satisfaction; but it is expensive, costing, I believe, three or four hundred dollars, and is not within the reach of a common farmer. It can only be owned by a company of farmers, who employ a man to go with and operate it. We have two of them in Cornwall, which do service there and the adjoining towns. The Bolles' machine goes on wheels, and is operated by cranks, and will take up a stone weighing six or eight tons, if we can find a rock that we can get between the wheels of that weight, and travel off with it. It takes two yoke of oxen to work it economically, and fifty rocks a day is a good day's work, with a skillful man to manage it, and three other men, and two pair of cattle. It cannot be operated to advantage in the hands of common farm laborers. I should not advise any man to get one for his own use, but if it can be owned in a neighborhood, where a man will go with the machine, to keep it in order, and take care of it, it is a wonderful help in clearing our rocky lands. We have a pair of them in Cornwall; one of them lighter, with large wheels, for wall laying, that have been constructed with very great care, and no expense spared to make them strong, so that you cannot rack them or break them. This machine is very efficient in removing boulders that weigh from two to five tons, and lie considerably buried beneath the surface.

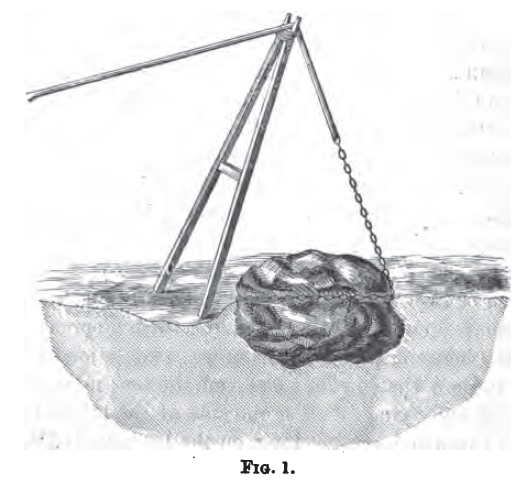

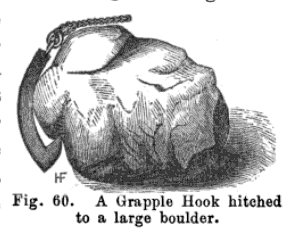

Then we have another instrument, in the shape of a cant- [p.120] hook, that is very efficient for a certain class of rocks. It is a large cant-hook, (fig. 2) that will weigh, with the necessary attachments, two hundred pounds or more. It is worked with two yoke of oxen, and it will take out stones weighing from half a ton to five tons, very rapidly. Two hundred rocks a day is about the working power of that instrument, under favorable circumstances, with one man to dig around the rocks, one man to drive, and another man to handle the cant-hook. That costs, well made, about twenty dollars. I have found this a very serviceable implement.*

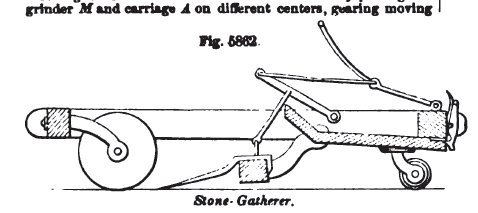

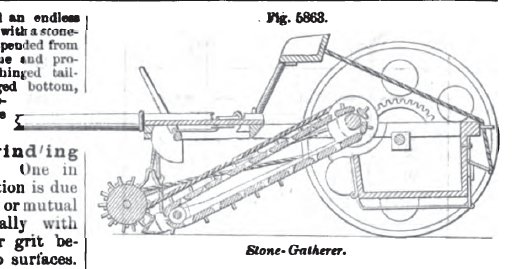

For the next size smaller stones, there is a Lyon rock-hook, that has been made in Cornwall, and used to a considerable extent for pulling bushes and rocks. It has a neap that goes between the cattle, handles like a plow with a pair of hooks in place of the plowshare, and you go along with it and scratch up the small rocks and stones, taking up those that will weigh a ton or more, but more especially the small ones. That is very efficient, and with one man to drive and one to hold, it will take out as many small boulders in a day as two men would in a week, with crow-bars. You can go over a piece of rocky ground, and cover the whole surface with the small rocks and boulders.

With regard to the other method—blasting—some rocks

[footnote] * The lever of the rock hook is of white ash, with the natural crook at the root. Length five and a half feet; seven inches square at the largest part, and tapering at the ends. The iron hook is attached one and a half feet from the lower end, and is steel pointed.

[p.121] are so hard that it is almost impossible to bore them. We have these blue stone, and hard silicious rocks, that it will take a man half a day to drill a hole to get the blast in, and so tough that you can hardly blast them when you get the hole. It is very unprofitable to blast such rocks. But those that are soft and moderately firm, and so flat as not to be easily handled otherwise, the readiest way is to blast them.

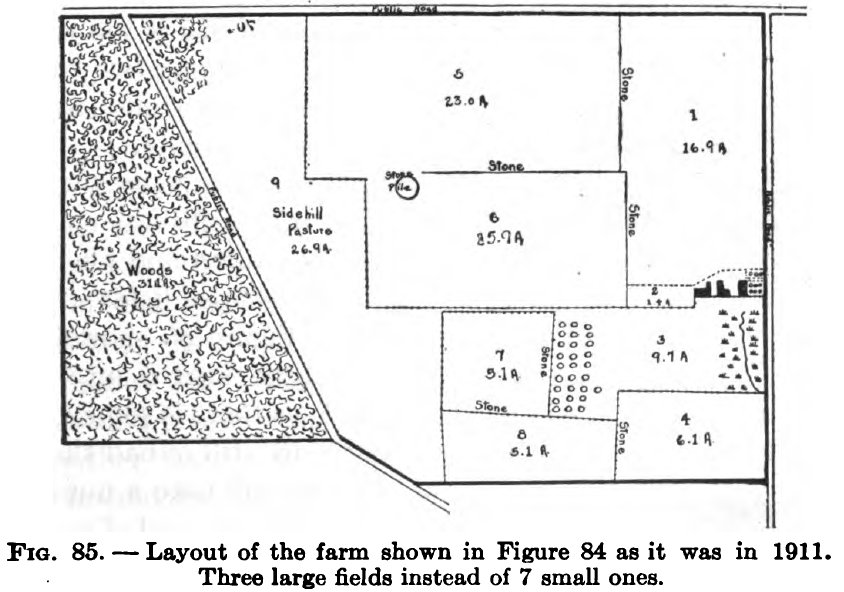

With regard to burying them, if you can dig in your soil, if it is of such a nature that you can dig without the liability of meeting obstructions beneath the surface in the form of other rocks, the most ready way to dispose of them is to make a hole and turn them in. You can easily dispose of very large rocks in that way, unless you need them for fencing.